Precision Tube Bending Capabilities & Tolerances | Great Lakes Region, Michigan

Advanced CNC Tube Bending

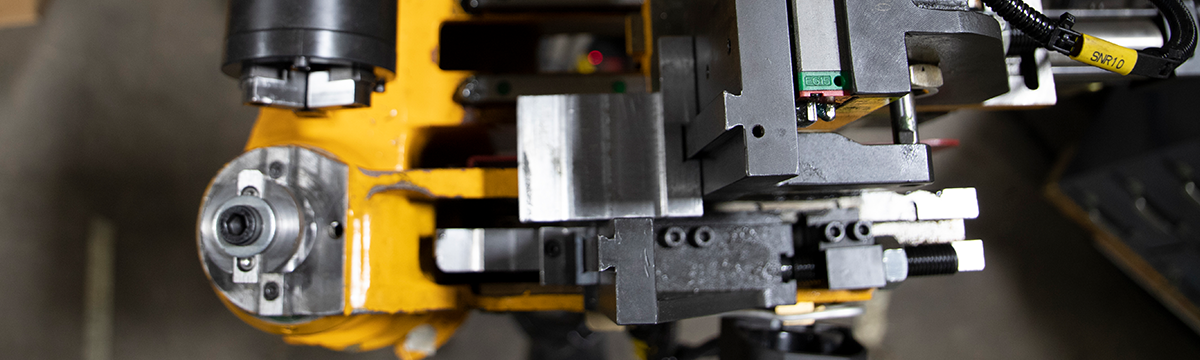

At Wooley Manufacturing, we specialize in precision tube bending services powered by the Horn Metric CNC18MBE, a hybrid CNC tube bender engineered for high-performance and tight-tolerance applications. Whether you're working with mild steel, stainless steel, or non-ferrous metals, our CNC tube bending capabilities ensure consistent, repeatable results across complex geometries and demanding specifications.

Key Features of our Horn Tube Bender

- Hybrid Electric/Hydraulic Drive: Combines servo-electric bending and tube positioning with hydraulic tooling actuation for optimal control and force.

- Dual-Stack Tooling: Enables both mandrel bending for tight radii and roll bending for large-radius sweeps.

- BendPro CNC Controls: Offers full simulation capabilities for precision programming and reduced setup time.

- Servo-Driven Axes:

- Bend-arm (C-axis) via planetary transmission

- Carriage (Y-axis) with push-roll capability

- Collet (B-axis) rotation for multi-plane bending

- Hydraulic Tooling Actuation: Clamp, pressure die, and mandrel systems are hydraulically driven with early withdrawal for wrinkle-free bends.

- Automatic Mandrel Lubrication & Tube Support: Enhances tool life and bend quality.

- Environmentally Friendly: Low power consumption, reduced noise, and minimal heat output.

Tube Bending Specifications

Tube Bending Tolerances

Our CNC tube bending process adheres to industry-standard tolerances, including:

- Bend Angle Accuracy: ±0.25°

- Bend Radius Consistency: ±0.010 in (±0.25 mm)

- Ovality Control: Maintained within ±10% of nominal diameter

- Wall Thinning: Typically less than 15%, depending on material and bend radius

- Repeatability: High precision across production runs due to servo-controlled motion and CNC programming

- Automotive and Off-Road

- HVAC and Refrigeration

- Aerospace and Defense

- Medical Equipment

- Industrial Machinery

Applications

Our tube bending services support a wide range of industries, including:

Whether you need prototype development, low-volume production, or high-volume manufacturing, our CNC tube bending capabilities deliver unmatched precision and efficiency.

Ready to Get Started?

✓ Free quotes within 1 business day

✓ 70+ years of manufacturing experience

✓ Serving Michigan and surrounding states

✓ Prototype to high-volume production

Get A Tube Bending Quote